US Aircraft Carriers Are Using 3D Printed Parts (For A Good Reason)

The technology behind 3D printing presents a use case for creating objects, components, and gear out in the field, quickly and at a low cost. The International Space Station, for example, has a 3D printer on board. It decreases operating costs for the station and lowers risks for astronauts since they can make mission-critical components right there. Back on Earth, 3D printers can be used for a variety of tasks, like printing car parts in limited selections or creating entire buildings relatively quickly compared to conventional construction methods. So it's not really a surprise to hear the technology is being used for naval warships. By using additive-manufactured (3D-printed) parts on aircraft carriers, the Navy has slashed lead times by over 70%, Naval Sea Systems Command (Navsea) said in a press release.

Wait a minute — the Navy is making plastic parts? No, not exactly. In one instance, Navsea printed a metal part, a valve manifold assembly, for its pump room on the Gerald R Ford-class aircraft carrier Enterprise (CVN 80). This is significant because traditional metal casting methods have longer lead times for complex parts, especially in smaller quantities.

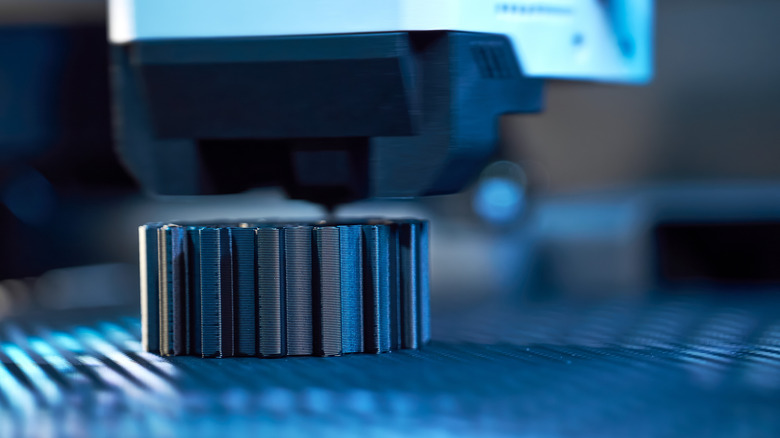

Many materials can work with 3D printers, from plastics and metals to resin and cement. In the Navy's case, the part was precisely printed by manufacturing company DM3D with metal, in a shipyard without molds and more involved processes. That's a huge benefit for naval warships with complex parts. They can be outfitted faster than usual, maybe even during crucial moments. The Navy has done this many times now with the help of partners. In the press release, Navsea said the technology is "no longer viewed as an emerging experiment, but as a readiness enabler fully integrated into planning, maintenance, and sustainment."

What else is the Navy doing with 3D printers?

To demonstrate the technology's capabilities, the Navy has collaborated with several additional partners to have custom parts printed. In another instance, Marotta Controls, an aerospace and defense supplier, manufactured a chilled water valve which was successfully installed on board a U.S. Navy ship. Marotta used what's called laser powder bed fusion to fuse powdered material layer-by-layer. The material was Inconel 625, a corrosion-resistant nickel superalloy.

Installing printers on warships is a recent endeavor, but it's not inconceivable to think that one day, they may be working in the middle of battle. The Navy did partner with the U.S. Coast Guard to print a piece of critical equipment from a polymer 3D printer installed on a submarine. And yet another partnership between the U.S. Navy, Australia, and the U.K. saw successful shipboard 3D-printed part installations on a fast-attack submarine, the USS Vermont. There are real-world cases of the Navy utilizing 3D printers in the field to great benefit.

Advancements with printed materials may introduce new benefits, as well. Researchers previously discovered a way to make plastic that's cheap, stretchable, and recyclable. It can be melted down easily and re-formed while still maintaining its strength, making it ideal for many applications. It's not a stretch to imagine innovative metals and other materials that could introduce similar properties. Any 3D-printed naval parts would see enhancements as a result.