Here's Where Electric Car Batteries Go After Their Lifespan Ends

What happens when the powerful battery inside an electric car reaches the end of its life? These massive lithium-ion packs, often weighing hundreds of pounds, are the beating heart of every EV. Though there is ongoing research to make EV batteries much lighter. They store the energy that keeps modern cars moving silently down the roads and highways, but like all technologies, they don't last forever. After years of charging and discharging, their capacity fades due to degradation. However, instead of simply becoming waste, most EV batteries today are given a second chance. They're either repurposed for stationary energy storage or broken down through an advanced recycling process that recovers valuable materials like lithium, nickel, and cobalt for use in new batteries.

This transition raises important questions: What challenges do manufacturers face as millions of EVs roll off production lines worldwide? Can the recycling infrastructure keep pace with the rapid growth of electric mobility? Does the ability to reuse and recycle these critical materials strengthen the environmental promise of EVs? Exploring how the industry tackles these issues reveals that an EV battery's journey doesn't end when it stops powering a car. It continues, helping to close the loop in a more sustainable energy future.

Are EV batteries recyclable?

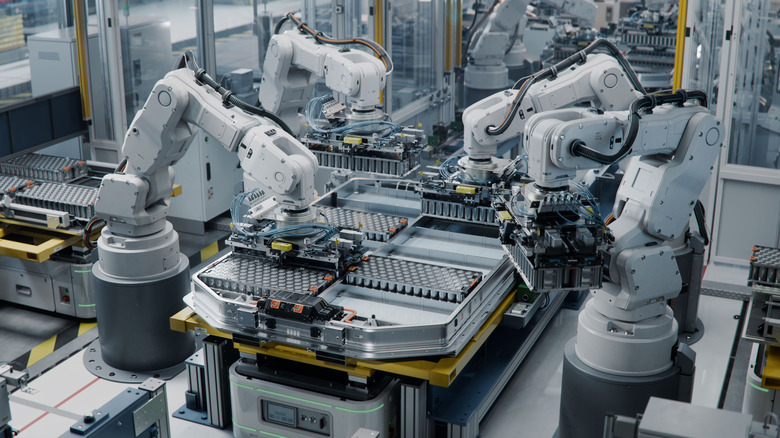

Yes, electric vehicle batteries are recyclable, and the process is becoming more refined as the number of EVs on the streets grows. When the battery reaches the end of its life, it doesn't simply get discarded. Instead, specialized facilities carefully dismantle it, breaking it down to its key components. Metals like lithium, cobalt, nickel, and copper can be extracted and returned to the supply chain. They're processed into raw materials for new EV batteries — some of which can travel miles on just minutes of charge – or for other industrial uses. This not only conserves valuable resources but also reduces the environmental footprint of mining.

A typical EV battery is mostly made up of metal parts, with plastic and other materials representing a small fraction of its weight. Still, plastic plays an important role in the insulation and housing of the battery. During recycling, plastic is separated from metals and can be repurposed, although most companies don't bother. Plastic doesn't have the same economic value as metals, but recovering it minimizes waste and supports a circular approach to battery production. Although the spotlight always falls on critical materials, every part of the battery, even the smallest plastic piece, has an important role in this sustainable cycle.

What's so critical about critical materials?

Inside every EV battery cell lies a cocktail of critical metals that make modern electric driving possible. Lithium, nickel, cobalt, and manganese are the backbone of the cathode, while graphite anchors the anode. Copper and aluminum serve as conductors, helping power flow efficiently. These metals are expensive and energy-intensive to mine. They're often tied to supply chain challenges, as well as environmental and ethical concerns about their mining. Recycling them has become a key strategy in securing the future of electric vehicles.

Several companies have already risen as leaders in EV battery recycling. In the United States, Redwood Materials, founded in 2017 by Tesla co-founder JB Straubel, quickly became a major force. Its process recovers more than 95% of critical materials from a used battery. They turn spent cells into raw materials ready to be used in new batteries. In Canada, Li-Cycle (recently acquired by Glencore) has developed a distinctive model known as "Spoke & Hub" in which local facilities shred used batteries into a dense, metal-rich powder called the "black mass." This powder is sent to centralized hubs for chemical separation of materials. Belgian company Umicore is a European pioneer in EV battery recycling. Its recycling operations achieve high recovery rates and feed these resources back into the region's growing battery manufacturing industry.

Is a second life for old batteries possible?

An electric car battery is considered depleted when its capacity falls to around 70-80 percent of its original strength. At that point, manufacturers can't guarantee it will deliver the range and the performance drivers expect. However, that battery is not yet useless. In fact, a battery with 70% capacity still delivers enough energy for less demanding applications.

There's an idea out there that such EV batteries should be given a "second life," though it has yet to materialize at a larger scale. Unfortunately, most activity in this area so far has been limited to demonstration projects. Automakers and energy providers have tested used EV batteries in stationary storage systems. That would smooth the renewable power supply or back up the power grids. Others envision these batteries being used in homes, where they could store electricity from solar panels or provide backup power during outages. In an industrial setting, they could help balance energy loads or serve as buffer storage for electric car charging stations. Yet while the concept is appealing, economics remains a major barrier. Brand-new lithium-ion batteries are cheaper today, reducing the financial incentive to buy, transport, test, and repurpose old ones. Until costs align and standardized systems are developed, the second life of EV batteries will remain more of a promising idea than a commercial reality.

The future of recycling EV batteries

As electric vehicles scale up worldwide, recycling their batteries will be central to keeping the transition truly sustainable. Current processes already recover most of the critical materials. But the future promises even cleaner methods as science develops more efficient techniques of recycling materials. Researchers are exploring ways to reduce the energy needed to dismantle and process used cells. They try to shift away from high-temperature smelting towards gentler hydrometallurgical or even bio-based techniques. These methods could cut emissions while still reclaiming lithium, cobalt, and nickel at battery-grade quality.

Another frontier is designing EV batteries with recycling in mind. If manufacturers standardize pack structures and use adhesives and casings that are easier to separate, the entire recycling chain would become faster, cheaper, and cleaner. Some companies are also experimenting with "direct recycling," where materials such as the cathode are recovered intact and refurbished. Making EV battery recycling greener means extracting less from the earth, wasting less in the manufacturing process, and feeding back into new production. The ultimate goal for EV battery recycling is to contribute to a truly circular energy system.