Robots Are Taking Over The Human Labor Industry, Starting With This Hyundai Facility

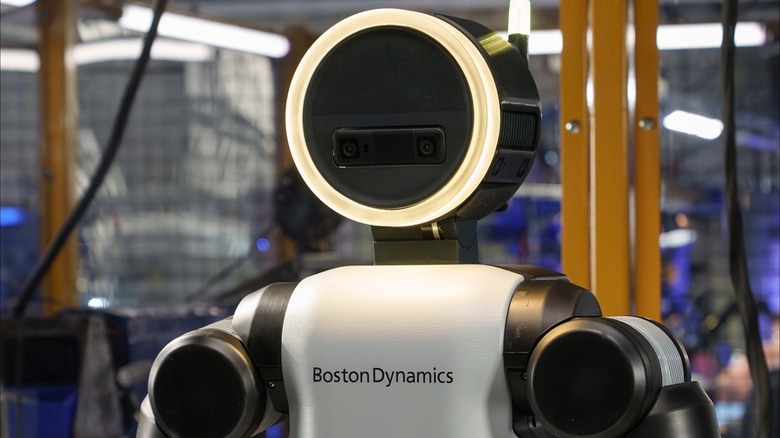

Decades ago, it was both the dream and assumption that humanoid robots would eventually take the place of human laborers in various industries and professions, particularly factories and assembly lines. While we haven't achieved complete robotic automation just yet, movements are being made ever so slowly to start training the first generation of laboring robots. One of these movements is occurring at a Hyundai facility in Georgia, where Boston Dynamics' signature robot, Atlas, is learning how to sort and sequence automotive parts.

Back in 2021, Hyundai made a substantial investment in Boston Dynamics' development of the bipedal Atlas robot. That investment has begun to bear fruit, as Boston Dynamics showed off the newest iteration of Atlas at CES 2026, demonstrating its impressive abilities to lift heavy objects, bend and rotate, and even scan and analyze objects with its tactile fingers. Atlas has already begun on-the-job training in a segmented corner of a Hyundai factory to begin taking the reins on some jobs from human workers.

Boston Dynamics' Atlas is being trained on simple tasks

The current version of Atlas is substantially more advanced than previous iterations that have been seen dancing and performing gymnastics routines on YouTube. As shown at CES, Atlas is equipped with a Gemini-based artificial intelligence produced by Google DeepMind and powered by Nvidia hardware. Rather than the previous algorithmic routines that governed its movements, Atlas can now learn and respond to external stimuli. The keyword there is "learn," however, advanced as it has become, Atlas cannot simply be dropped into a factory and put to work. It needs to learn a task inside and out before it can perform it reliably and consistently.

This is why Hyundai has placed Atlas models in a segregated section of its Georgia factory to begin training them on tasks like sorting roof racks or sequencing parts for assembly. Atlas will need to practice these tasks for at least several years before it has accumulated enough training and data to perform them on the real assembly line.

"Rather than having a set of predefined, loaded tasks onto the robot, we think robots should understand the physical world the same way we do," Caroline Parada, senior director of robotics at Google DeepMind, said at CES. "They should be able to learn from their experience. Should be able to generalize new situations and get better over time. So whether it is to assemble a new car part or to tie your shoelaces, robots should learn the same way we do from a handful of examples, and then get better very quickly with a little bit of practice."