Are 3D Printers Actually Reliable Now? Here's What Users Say

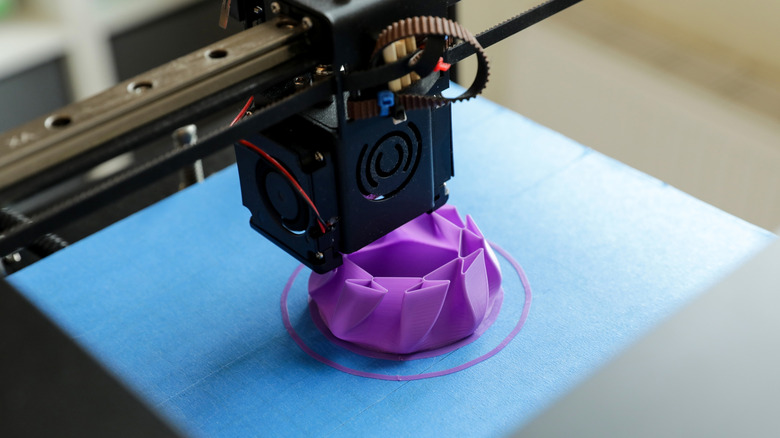

When 3D printers first arrived, the reality sadly often fell short of the sci-fi dream that these kinds of products promised to their owners. Early models weren't reliable at all, forcing their users to spend more time troubleshooting possible issues, like clogged nozzles, instead of actually creating new models. However, this changed in the last few years, as with new models of 3D printers being released, it became more common to use these devices as "plug-and-play" devices and have high-quality results with more consistency than before, especially when paired with the right printing accessories.

At the same time, despite the upgrades that 3D printers have received with newer versions, their reliability is still dependent on the operator. As many users point out, the resulting output from these machines is dependent on variables that only the user can manage, like slicer settings and filament quality. Even humidity can play a huge role in the final quality outcome of a 3D model. Someone who understands how to tweak those things will experience better results overall with their printing projects.

In the end, the fact of whether a 3D printer is or isn't reliable can vary. While the most modern hardware has received some upgrades in how well it works compared with their predecessors, the experience of each user may vary significantly based on their skill level and desire to learn more about how to operate these machines.

Modern 3D printers are significantly more reliable nowadays

Overall, 3D printers have become more reliable with hardware upgrades that they have received in newer models, making it easy for users to resolve some issues that were common in the past. Older models, for example, required some manual calibration using a sheet of paper for bed leveling, making a critical part of the process more prone to human error. Most of the recent models, however, have more sensors that compensate for uneven surfaces more easily.

Many users also point out that new models of 3D printers are designed as more complete ecosystems, with sturdier frames, improved motion systems, and better thermal management. These modifications have helped reduce some of the mechanical inconsistencies that early models had. Additionally, some features, like automatic bed leveling, filament sensors, and more stable firmware, have helped minimize some common failure points.

At the same time, while the newest models are made with more reliability in mind, some trade-offs are also made, especially in terms of repairability. As manufacturers focus more on delivering "plug-and-play" experiences for their buyers, certain models rely on proprietary parts, locked firmware, or closed ecosystems to achieve that consistency. While this approach can reduce many frustrations that a new owner may have, it also limits how much control each user has over their product when compared to earlier models.

3D printer reliability is still dependent on each user's knowledge

Despite all the updates that 3D printers have received in new hardware, another important aspect that heavily influences the reliability of each model is the knowledge of the person who is using it. With models becoming more plug-and-play, it becomes easier for new users to start making their models than before; however, they don't eliminate the need for proper configuration by the operator. So, even if some mechanical problems are fixed in recent models, they can still produce inconsistent results.

Many 3D printer owners point out that most printing issues aren't because the hardware has failed, but because of problems that require human oversight during the process. Slicer settings, such as layer height, print speed, temperatures, and support generation, directly affect print quality and success rates. Also, the filament quality used by the 3D printer can influence the results that you get, regardless of how advanced the printer itself may be.

Another point is that, when searching for STL files for your 3D printer, it's also important to see if they have good quality, especially when looking for 3D printing projects to make first, since a poor one can lead to a poorly printed model. Even a more advanced device, like the Bambu Lab X1C, despite having AI failure detection and advanced sensors, cannot correct a flawed STL file.