One Of The Strongest Engineering Materials In The World Can Now Be Used For 3D Printing

Tungsten carbide-cobalt (WC-Co) is the go-to material for tool edges and anything that typical hardened steel tools can't touch because it's abrasion-resistant and tough. That strength also makes it a nightmare to manufacture into custom shapes. In most factories, WC-Co parts are made by pressing metal powders and then heating them in a high-temperature furnace. It works, but it's an inefficient manufacturing process when it comes to complex forms, and the raw material going in produces a less-than-ideal yield.

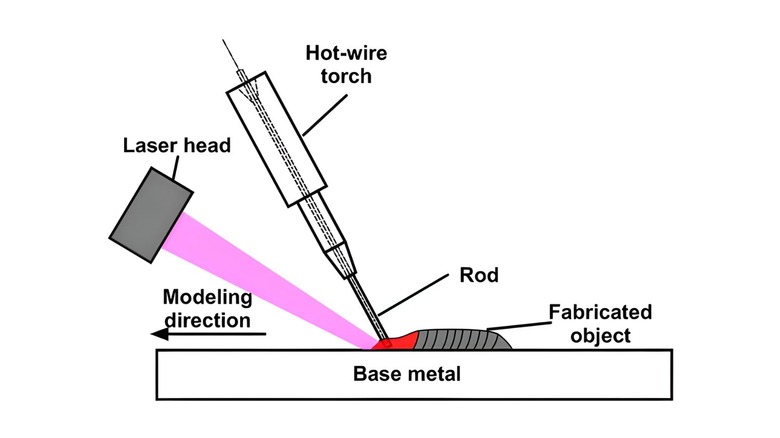

But instead of making a tool from scratch, why not just add WC-Co where needed instead? Hot-wire laser irradiation, or hot-wire welding, is the answer according to researchers at Hiroshima University. This process softens the metal rather than melting it down and causing overheating issues, with the process bringing the material to a point where it can be fused without losing its structure. With tungsten and cobalt being expensive metals, this process will provide a higher yield and can be compared to metal 3D printing, given the layer-by-layer manufacturing method.

This could be a groundbreaking moment not just for tool manufacturing, but for 3D printing down the line, too. Hot-wire laser irradiation combines a laser with a pre-heated wire so material can be added while keeping tight control on heat. Researchers tested two build styles, and the hard work is all in the details, which is to be expected for such a complicated process.

How the new method works

One approach led to a chemical breakdown of tungsten carbide near the top of the build, which can create defects. But the most successful attempt relied on better temperature control and an extra nickel-based alloy inserted between WC-Co layers that helps the structure form properly. Think of it as an adhesive to create a solid piece of tungsten carbide-cobalt. This could turn into a metal 3D printer setup eventually, as there are already 3D printers that can handle stainless steel, aluminum, and tool steel such as MPRINT.

Following this discovery, the team reported that it could make parts with hardness above 1400 HV. That's twice as tough as hardened steel and good enough for milling, parting off, and turning with interrupted cutting. This process also avoids defects and decomposition, which could arguably also spark ideas for safe metal 3D printers for enthusiast use at home, the U.S. Navy certainly has the same idea.

Researchers now looking into improving crack resistance and making more complex shapes, with the former being the main challenge with Tungsten Carbide in general thanks to carbon . This is why tools are usually coated or tipped with the metal, with the main material being a steel alloy or hardened tool steel that has some flexibility.