8 3D Printer Projects That Are Actually A Waste Of Your Time

3D printers are currently among the most impressive devices you can buy for at-home use, and they're the closest thing we have to replicators from Star Trek. These desktop mini-factories can make all sorts of objects from raw material, provided you have the necessary blueprints. Soon, giant 3D-printing robots might even help solve the housing crisis — but we're not quite there yet.

3D printing technology has advanced by leaps and bounds in recent years, and we have significantly more reliable models on the market now than we did before. But it's still fairly easy to overstate what they can do. That's why you often see 3D printer projects that sound good in theory (and look cool in photos), but don't make sense in real-world applications.

Some uses can't work due to the fundamental limitations in current 3D printing technology, specifically as found in Fused Deposition Modeling (FDM) machines, which are the most popular types of 3D printers. In these devices, a filament of material — usually plastic — is fed through a hot extruder to build up objects layer by layer. While this method is extremely versatile, it has inherent limitations that make it unsuitable for certain applications. Think again before wasting your time with prints you won't use, up to and including the ones listed below!

Lego-compatible bricks and click-fit toy parts

Lego lost its patents many years ago, so it's perfectly legal for "Lego-compatible" bricks to exist and even be sold right next to the beloved original. This also means it's perfectly okay to print your own Lego-compatible bricks on a 3D printer. But in practice, it's probably easier, cheaper, and better for your mental health to buy genuine Lego, or at least one of the many quality injection-molded compatible brands. Why? It all comes down to precision and tolerances.

Lego's product is successful because its injection-molded bricks are made to such high standards. There's barely any variation between one brick and the next. They've calculated the exact friction required to make bricks both stick together and detach reliably.

While you might have some success with printed bricks, the results are just too inconsistent. Even bricks printed in the same batch can fail to connect properly. The piece's position on the build plate, as well as the printer's calibration settings, can make differences in precision prints that normally don't matter, but certainly do for Lego-style bricks. By extension, this issue also applies to "click-fit" style toys that require similar tolerances. However, if a model has been designed to account for the tolerances of typical FDM machines, it won't be a problem.

Bottle openers and small lever tools

Although plenty of bottles are now designed with metal twist-off caps, many still require a bottle opener for you to get to the liquid goodness within. (Some people use their teeth, but 0 out of 10 dentists recommend doing that.) For such a common household item, it's an oddly popular print. On the Printables website alone, a search for "bottle opener" yields over 600 results. There are plenty of cool designs, and the ones meant to open plastic soda bottle caps are indeed useful. But printing a bottle opener for metal caps doesn't make as much sense.

The best bottle opener prints require a metal part, such as a coin, to be used properly on metal. Soft PLA wouldn't stand up long to repeated contact with metal caps, and neither would ABS filament, which is even stronger. Whether your opener uses a metal bit or not, 3D-printed levers of any kind have to compensate for the weakness of the production method to withstand torque. A 3D-printed bottle opener would probably wear out quickly, and in the end, you'd just have to print a new one. Ultimately, durable metal bottle openers are so cheap that there's little reason to print plastic ones, besides for novelty's sake.

Food-contact items like cups, cutlery, and containers

Many of us use plastic products with our food, which is, unfortunately, one of the reasons why microplastics have made their way into the human brain. And since we're so used to using plastic utensils of all kinds, it might not shock you to learn that there are many food-related 3D-printed models out there for containers, cutlery, cake molds, and so on.

The problem is that whatever you're printing is almost certainly not safe for contact with food. Not even as a disposable item. While a specific filament might be graded as "food safe," that doesn't mean the items you print with that filament will end up being food safe. For one, the porosity of the print makes it a haven for bacteria. This isn't an issue with injection-molded plastic utensils and containers, though. Those can easily be washed and sanitized.

However, your 3D printer's printing bed is almost certainly not a safe place to make items that touch food, even if they're only meant for a single use. What other filaments and additives have been through your extruder? What chemical residue could come into contact with your print? Is the inside of your printer free of harmful bacteria or toxic substances? Your answer, at best, is most likely "I don't know." It's not worth the risk!

Glow-in-the-dark prints

The list of interesting 3D printer filament options is exhaustive, but many people jump at glow-in-the-dark filament options specifically. Glow-in-the-dark filament is just regular PLA filament that's been infused with phosphorescent material, which, after absorbing light, emits light again at a particular wavelength. It's a fun filament when printing decorations for Halloween night, but if you spend any time working with glow-in-the-dark filament, you'll soon realize that the juice is rarely worth the squeeze.

The biggest issue is that those particles are hard minerals, so they could wear out a soft copper printer nozzle in no time. One roll of glow-in-the-dark filament can be enough to wear out a copper nozzle completely, but even hardened nozzles can suffer higher levels of wear and tear.

The other problem is that you need a significant amount of material to achieve a decent glowing effect. This means you need to use more material in your infill, increasing the amount of filament that each print uses. This makes glow-in-the-dark PLA — which is already more expensive than plain filament — even less economically viable. It's a fun novelty, but after you've cleared your tenth filament clog or failed print in a day, you'll start to question whether glow-in-the-dark printing was a bright idea after all.

Weight-bearing parts and load-bearing prints

Plastic objects can be incredibly strong. There are plenty of injection-molded plastic parts and products out there that can withstand plenty of weight and force. However, it's not just the material itself that makes these parts durable: it's also the manufacturing method. An FDM 3D printer lays down material in thin layers that fuse and adhere to each other. This creates unique weaknesses in the final product. So even when 3D-printed parts look injection-molded, it doesn't mean they're just as strong as their injection-molded counterparts.

Because of how FDM prints are made, their structural strength is directional. This is separate from the strength of the design's geometry itself. That's why a print can be weakened or strengthened just by changing its printing orientation. This, of course, changes the direction of the layers relative to the print itself.

If the direction of force doesn't align properly with a print's layers, the print is likely to fail along those lines. If a part is meant to take stresses from multiple directions, there's no easy way to compensate for that in a single printed component. You could design a piece to account for such weaknesses, and you could also use stronger filament (like carbon fiber) to strengthen your prints. But, in general, FDM 3D prints are better suited for non-load-bearing uses — and they're definitely not ideal for printing things that are structurally important. You wouldn't 3D print car parts, for example.

Containers and prints meant to hold water

3D printers can output geometric designs that would be difficult, or even impossible, to recreate with injection molding. You may have seen unconventional 3D-printed vases at markets, on websites, and even beyond — but have you ever seen them with real flowers in them?

If you print one of these vases yourself and fill it with water, you'll realize quickly that your seemingly solid print can't hold liquid. Even at the finest settings tuned to precision, FDM printing does not inherently produce seamless surfaces that contain water. Water slowly but surely makes its way out of FDM-printed vessels owing to micro-gaps that exist between their print layers.

You can, of course, chemically treat your prints to prevent water from escaping them. But at that point, you're throwing away most of the benefits and convenience of 3D printing itself. Some objects that you might have designed to hold water won't be suitable for this approach anyway, so think twice — or even thrice — about mixing liquid and FDM 3D prints. Otherwise, prepare to spend some quality time with a mop and bucket.

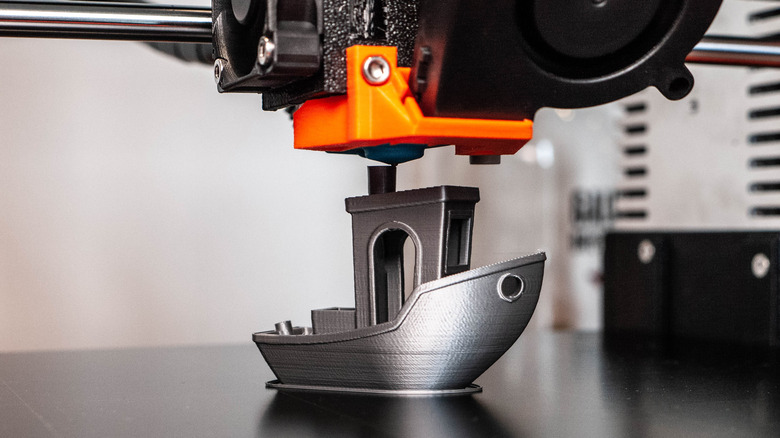

Outdated benchmark prints and test models

3D printers require calibration and testing at intervals for a few reasons. Wear and tear can alter the geometry of your printer over time, internal sensors might start drifting, or the phase of the moon might be throwing your printer off. (That last one isn't really true, but it can feel like that sometimes.) After calibrating or tuning your printer, you can print a performance-testing benchmark model. This is to see if your printer is working correctly, if you've improved its quality output with an upgrade or updated settings, or — in some cases — to check if the claims on a printer's spec sheet are true.

However, modern 3D printers work so well now that early benchmark prints like the beloved Benchy Boat pose no challenge to even poorly calibrated systems. A budget CoreXY 3D printer, for instance, can spit out a flawless Benchy in a just a few minutes.

It's important to carefully select a benchmark model that tests one specific thing. You can also choose a benchmark print that gives you precise, readable results, such as for marked overhang angles. Printing tests can even show you exactly how tight the tolerances are on your system with progressively harder intricacies. Great test print options include the all-in-one 3D printer test and the torture toaster.

Tabletop miniatures printed on FDM printers

Injection-molded figurines are fixtures of tabletop games like Dungeons & Dragons, Warhammer 40K, and similar titles. They represent characters, enemies, military units, and other important pieces in the game, so many players enjoy painting them meticulously. As anyone who's dipped even a pinky toe in games like Warhammer 40K will tell you, the official figurines aren't cheap.

So, in recent years, players have turned to 3D printing to make their own pieces. This may indeed be cheaper than buying official products, even when you consider your printer's upfront cost. However, as good as FDM printers have become, the level of detail they can produce isn't anywhere near what injection-molding can achieve at the scale of Warhammer 40K figurines. This isn't true of resin 3D printers, but those come with their own costs and practicality issues.

In our experience, larger-scale painted figures can work well with FDM printers, but the quality gap is enormous for actual gameplay scale. In the end, unless you don't care much about fidelity, it's better to buy the official figures instead. You could also get custom figures made by someone who specializes in resin printing. Should you ever wish to make resin prints yourself, you'll need the right setup to deal with the toxic chemicals and messes involved with the technology. FDM printers are still great for printing landscapes and other large features, though, so a hybrid approach could be the way to go for this use case.

Don't waste your time or your filament

While 3D printing is cheap in an absolute sense, spending time and resources on prints that will ultimately be useless isn't free. You may not mind the material cost of a print, but don't forget: Time is also money! It might be better for your printer to sit idle instead of undergoing unnecessary wear and tear from printing projects you probably won't ever use.

As 3D-printing technology improves over time, one day we might be able to say goodbye to 3D printing limits altogether. And at that point, maybe you'll be able to print your own food-safe coffee mug that actually retains your coffee. However, that day is not today.

Instead, there's a plethora of interesting and useful 3D-printed projects you could commit some time to. Your printer will thank you, and by the end of it all, you'll have far less plastic junk to throw away.